Carpeting for your Home

Carpet

Knowing how carpet is made can be very advantageous. The different materials that make up various carpets help us understand and evaluate their performance aspects: why certain carpets are easier to install, why some wear better, longer, and why others are easier to care for and clean.

How it's made

Tips

- Thicker is not always better. For instance, high traffic areas need lower profiles to avoid matting and crushing

- Tight twists in the yarn perform better than loose and frayed

- Firm and dense pile equates to higher quality

- The more backing visible, the less dense and durable

STYLE

Material & Fibers

Fiber is the basic material of makeup of carpet. 90% of carpet is synthetic, while the other 10% is mostly wool.

1. Nylon

- 75% of carpet is made of nylon

- Performs well overall

- Nylon is the leader in: appearance retention, fade and heat resistance, soil and stain resistance, color and styling

2. Polypropylene

- Introduced in the late 1950's in Italy

- Not as resilient or resistant to abrasion as nylon

- Naturally stain and fade resistant

- Resistant to moisture

- Limited range of color options

- Most often used in loop pile constructions

3. Polyester

- Introduced to the carpet industry in the mid 1960's

- Well accepted for bulkiness, color clarity, and good stain and fade resistance

- Not as resilient as nylon, but still performs well

4. PET by Mohawk

- 100% recycled material

- Plastic bottles are collected, separated by color, and then ground and melted

- Great color clarity, stain resistance, durability

- Keeps over 3 billion bottles out of landfills!

5. SmartStrand

- Eliminates shedding

- Highly stain resistant and durable

- 37% renewable materials

6. Wool

- Natural fiber

- Since wool is a natural fiber, it ranges in color from off-white to black, with many earthen tones between.

- Wool doesn't stand up to abrasion and moisture as well as synthetics, it cleans well and is known to age gracefully.

- Most expensive carpet fiber

- Primarily from New Zealand, Argentina, and the United Kingdom.

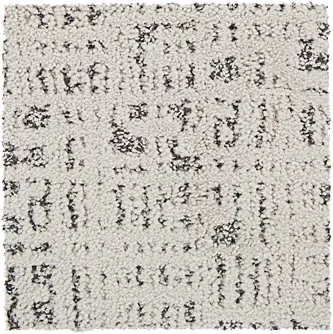

7. *Berber

- Considered a type of carpet construction, rather than fiber

- The name, Berber, originates from North African sheepherders

- Berbers produced coarse wool, with color flecks in their yarns

MAKING THE CARPET: A 3-PART PROCESS

Step 1: Tufting

- Weaving the synthetic or staple fiber into a primary backing material

- The tufting machine has 800 to 2000 needles, like a sewing machine to pull the yarn through the primary backing material

- The tufting machine is 12 feet wide; its needles penetrate the backing and a small hook (looper) grabs the yarn and holds it in place

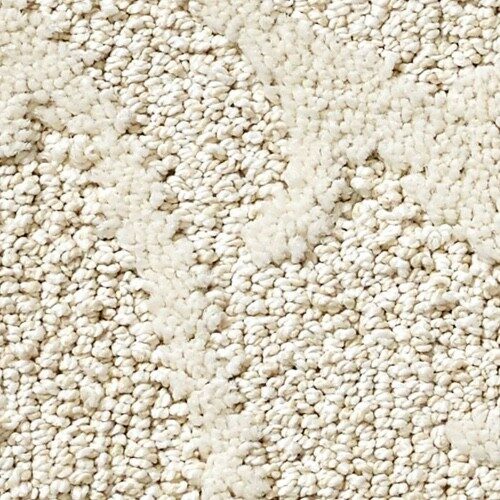

Loop Pile Construction

- Holds appearance well

- No exposed yarn tips

- Only sides of the yarn are exposed to wear and stress

Alternative Step

- Sometimes the looper cuts small loops creating a cut pile

- The lengths of these pieces are called pile height

- In order to create pattern on the surface, cuts are programmed to cut only some of the loops

Step 2: Application of Dye

Two dyeing processes

- Yarn Dyeing/Pre-Dyeing: color is applied to the yarn prior to tufting

- Good side-by-side color consistency, large lot sizes, and uniformity

- Carpet Dyeing: applying color to the yarn after tufting

- Greater color flexibility

Carpet Dyeing Methods

- Beck/Batch Dyeing: Stitching the ends together, then running the tufted carpet loop through large vats of dye and water for several hours.

- Ideal for small runs, heavier face-weight products

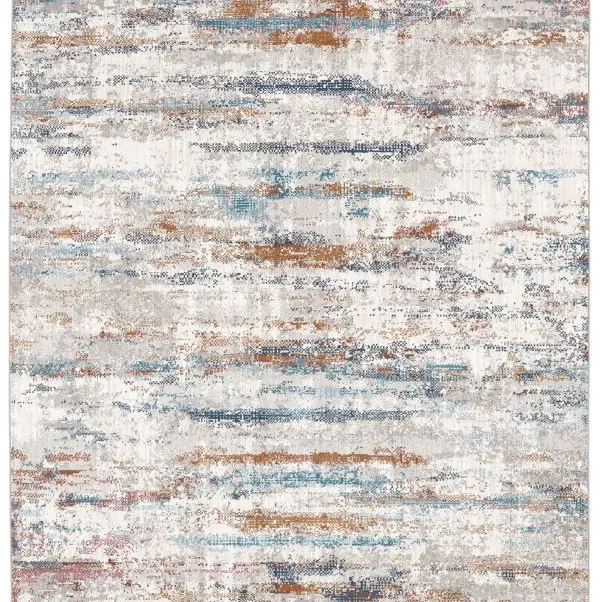

- Continuous Dyeing: Similar to Beck dyeing but carpet is also run through processes other than dyeing

- Applies color to the face by spraying or printing, also to create multicolor or patterned effects

- Screen Printing: Color is applied through 1-8 silk-screens

Step 3: Manufacturing the carpet

- Finishing Process: A single, five-part, production line completes the final construction stages

-

- Latex: A coat of latex is applied to dyed carpets.

- Secondary Backing: A layer of woven synthetic polypropylene is applied

- Shape Preservation: The two parts are squeezed together in a large heated press and held firmly

- Shearing: Loose ends and projecting fibers created during the tufting process are removed to help with yarn tip definition

- Inspection: Carpet is checked for color uniformity and defects before rolled, wrapped, and shipped, ready for installation