All About Carpet Dyeing

We love all the gorgeous shades that carpet adds to a room scene, soothing tones that help us unwind effortlessly along with the soft pile underfoot. If you have ever wondered about the different ways that carpet is dyed, we are taking a deeper look at the processes that lend outstanding color to the carpet we enjoy in our homes:

Common Carpet Dyeing Methods

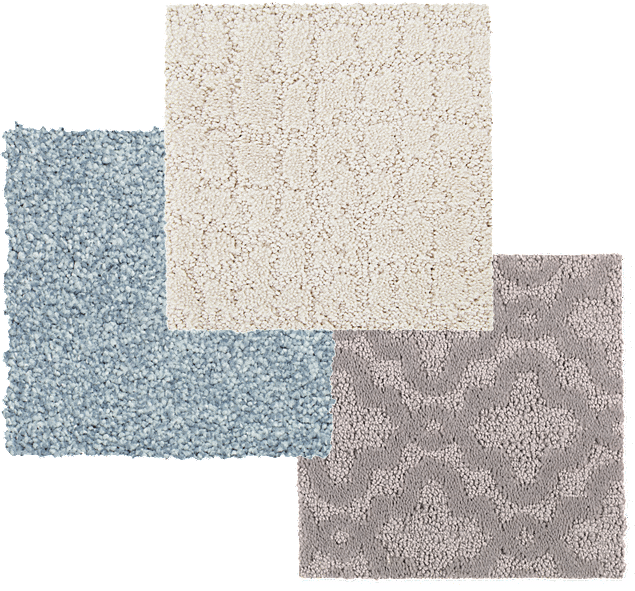

Solution Dye is for synthetic fiber only, and the color goes into the product when it is still in liquid state and before extrusion. We call this “the carrot”, meaning the color goes all the way through the yarn.

- Pro: More fade resistant + Consistency between dye lots

- Con: Limited in color selection

Continuous Dye is, by far, the most common dyeing method, which is applied on a conveyor belt where the dye is sprayed on or dragged/dipped in a bath of dye. The carpet continues on the belt, is dried, and then rolled up at the end of the line. We call this “the radish”, meaning the color is on the surface.

- Pro: Cost efficient + Variety of colors

- Con: Fades in sunlight and over time

Piece Dye is typically another way to refer to Beck Dyeing. Becks are essentially similar to big washing machines, and they come in different sizes.

- Pro: Vibrant colors + Less likely to side match

- Con: Time-consuming + Expensive

Additional Carpet Dyeing Considerations

All carpet will fade if faced with strong direct sunlight for extended periods of time. Some fiber types, regardless of how they are dyed, fade more readily than others. Continuous-dyed products do not fade more quickly than beck dyed products. Solution-dyed products are more fade resistant. Beck-dyed products are generally more likely to side-match* than continuous dyed products.

Some dyeing is sprayed on, the Militron machine from Milliken is one example. The pattern is sprayed onto the surface of the white yarn, and if you spread the tufts, you can see that the dye is only on the first part of the yarn tuft.

*What Is A Side-Match? A side match is a color discrepancy. Sometimes when you seam carpet together, there is a color difference between the two pieces of carpet that can be seen at the seam. There are a number of causes for that in the manufacturing process: If the temperature of the dye varies even slightly, the color will take differently and can only be seen when you seam the carpet farther down the roll with the carpet above it.

Beck dyeing very rarely has that problem as the whole piece is dyed together at the same time in the same situation. Hand-tufted items in particular have problems matching in pattern and texture, in addition to color. Machine-tufted products usually don’t have texture differences but patterns can certainly run off. A good installer can usually adjust the carpet to make the pattern match by stretching one of the pieces more aggressively.

Other Carpet Dyeing Methods

Skein Dye is yarn dying but not solution-dyeing and is only for natural (mostly wool) yarn.

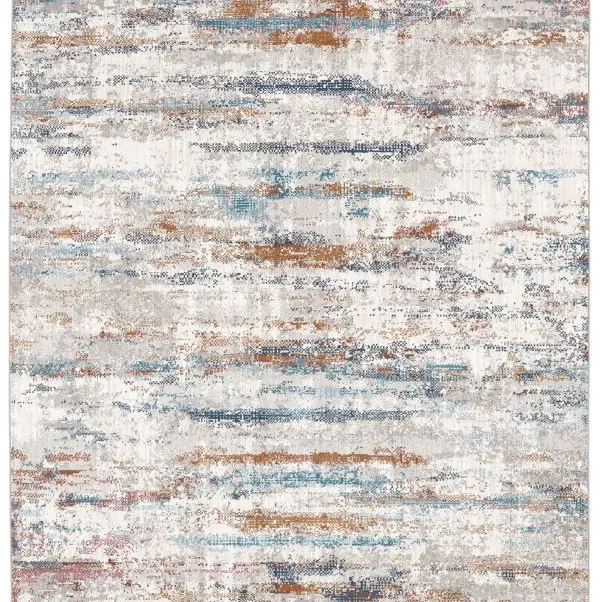

Cationic Dye is a way to get multiple colors on the same carpet by using yarns that take the color differently, because those carpets use differentiated yarns that take the dye differently. This can even result in totally different colors!

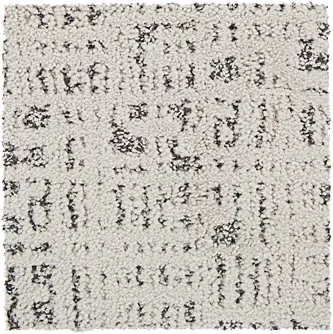

Space Dye is used to create flecked items that have a mostly solid color with frequent but random flecks interspersed.

Your beautiful carpet awaits! If you are looking for additional guidance through the process of purchasing quality carpet that will last in your gorgeous home, contact our helpful staff at Roberts Carpet. We can help you find the ideal carpet style and help you plan your next flooring project with stunning soft surfaces.